Clean equipment is essential for superior performance and avoiding expensive problems!

Mixing materials of any type is characteristically a messy job. And many materials are hard to clean. The result is that the mixing equipment is often not adequately cleaned, and the compound builds up over time. This build-up reduces the machinery's performance and reliability.

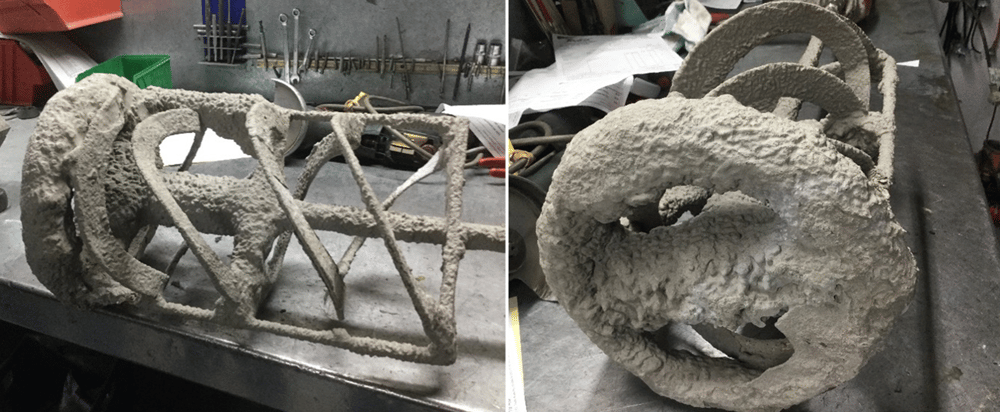

These photos show an extreme case of build-up on the mixing paddle.

There is a reason athletes don't compete in gumboots weighted down with mud and dirt. The stakes are high, and peak performance is essential.

In the industry of mixing scientifically engineered coating materials, correct and complete mixing is critical to achieving the right result. Without proper mixing, the quality and appearance of the finished product will be inferior. Inferior results will lead to complaints from the property owner, product failure, and expensive repairs. These inferior results are not a material fault; they result from incorrect mixing, and responsibility lies with the applicator.

Clean equipment is ESSENTIAL to allow the Portamix machines to achieve the high- performance they are designed for!

The Portamix mixing canister and mixing paddle profiles are designed to work together to produce material flow to mix fast and thoroughly. The clean edges of the mixing paddle break up lumps of powder, shear colors, lift aggregate, and create a smooth flow of material to ensure everything is blended. Like ice on the wings of an aircraft rob it of lift, so does a build-up of the compound on the mixing paddle or canister rob the Portamix of its ability to thoroughly mix the material.

In the photo on the left, you can see that the two lower helix ribbons are severely deformed. Clean equipment is easier to check and maintain to keep the mixer operating at its design efficiency.

Reducing Maintenance

Can you imagine how much extra load is on the motor when trying to mix a full batch of material with the paddles above?? Instead of a smooth, high-performance mixing paddle, the motor is being dragged down by trying to spin a heavy, inefficient mixing paddle.

Gearbox wear is accelerated significantly, and the motor's increased load is likely to cause the motor to burn out. This kind of failure is not a warranty issue; it is simply failure due to abuse – an unnecessary cost for the operator!

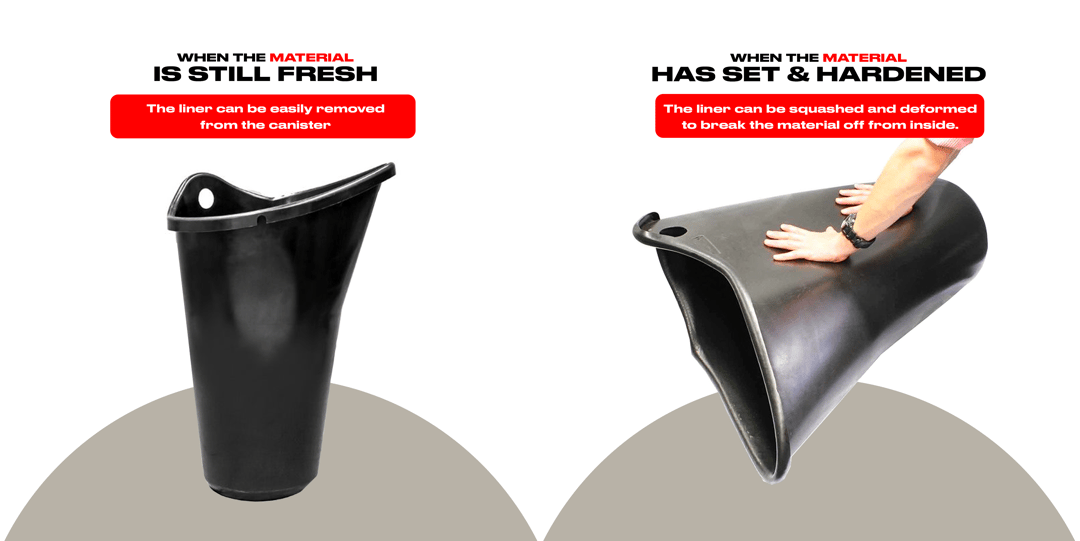

The REMOVABLE LINER makes cleaning the mixing canister much easier!

The liner can easily be removed from the canister and cleaned with while the material is still fresh. Alternatively, when the material has set and hard inside the liner, the liner can be squashed and deformed to break the material off from inside.

The helix will generally require scrubbing and washing down to get properly clean. If the material mixed is water-based, running it in a canister full of water will help get a lot of material off initially but it won't get it properly clean.

The easiest way to clean the mixing helix is to lift the motor mount up and lock it in the upper position in the mounting column. The helix can then be scrubbed and washed down easily.

REMEMBER: Clean the underside of the helix ribbons as well. Material is often not seen there and is not cleaned off.

*CONSIDER WASTE DISPOSAL REGULATIONS - DISPOSE OF WASTE MATERIAL RESPONSIBLY*

And that's why Portamix is your one-stop solution for all your flooring needs - straight from the "experts"!